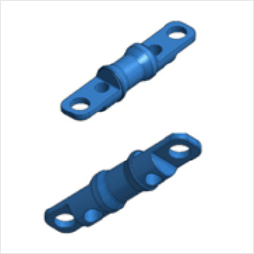

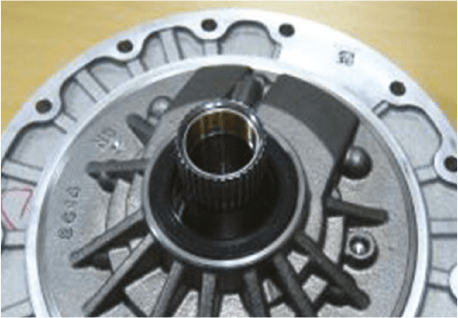

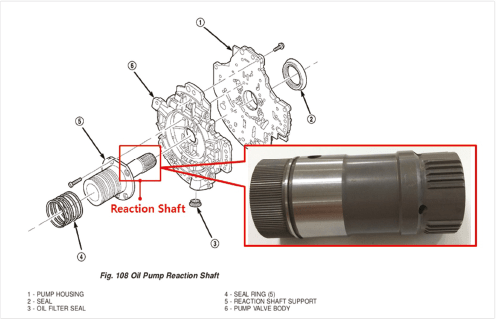

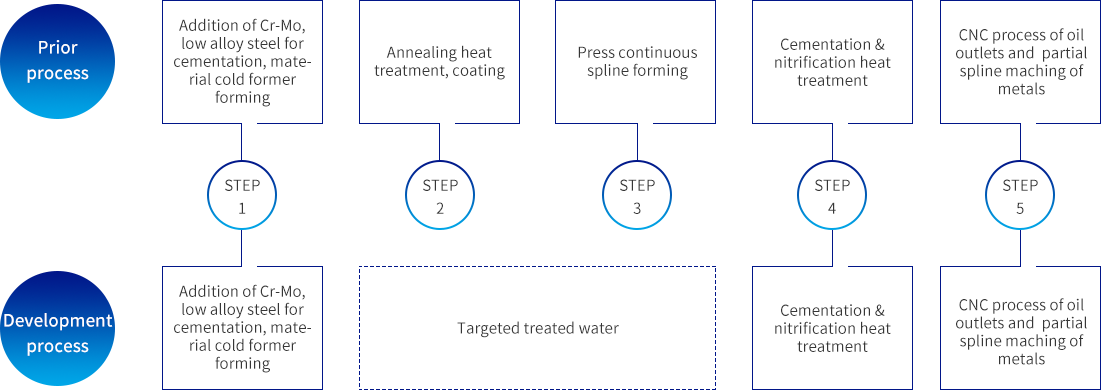

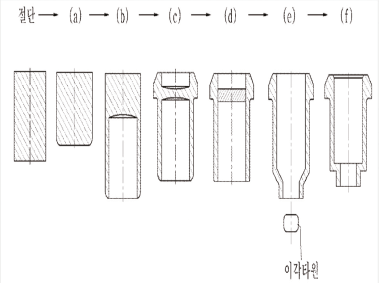

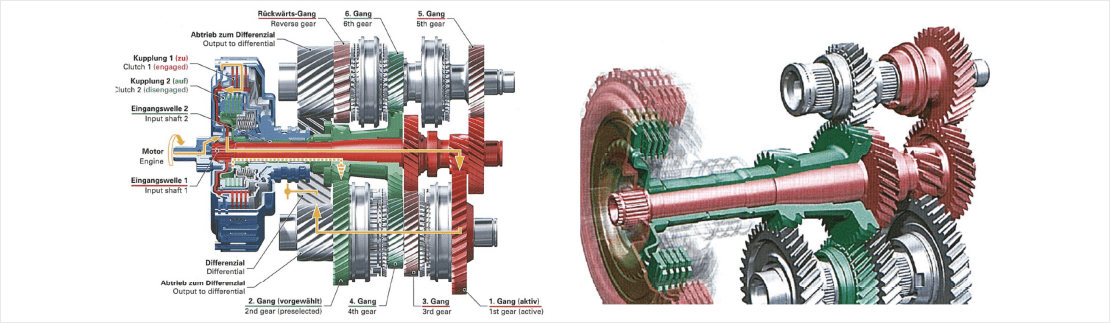

Manufacturing method of reaction shaft of an oil pump for vehicle transmissions. Reaction shaft of the oil pump for vehicle transmissions

formed by this. The present invention is the manufacturing method of reaction shaft of the oil pump for vehicle transmissions which form gear

by alternating the gear section and the lubrication section in the end zone and is about the reaction shaft of the oil pump for vehicle

transmissions through this.

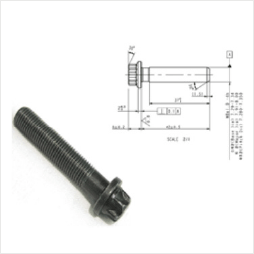

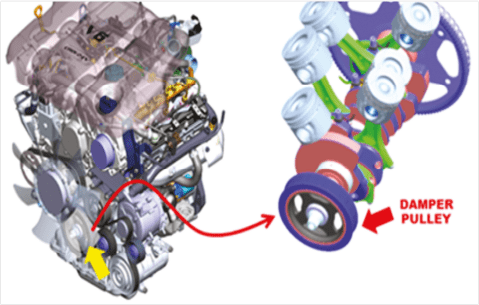

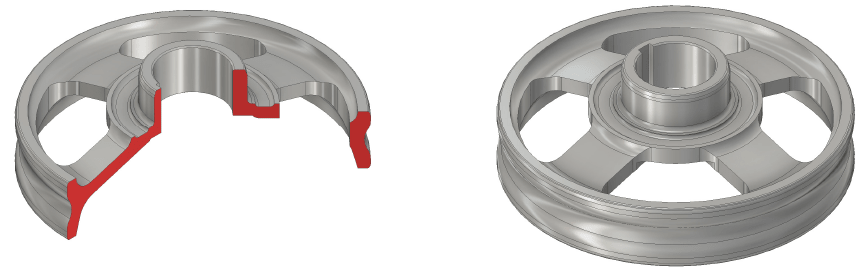

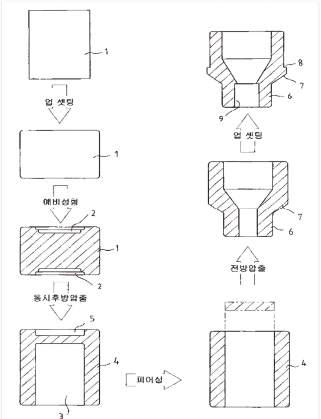

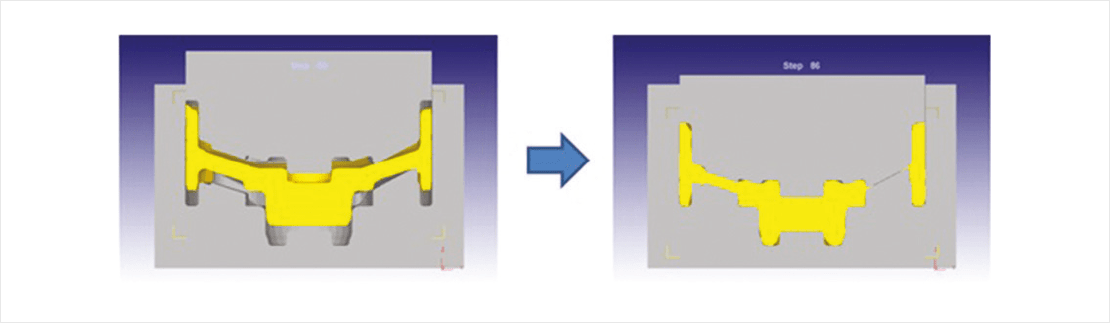

The present invention is about the manufacturing method of damper pulley which prevents materials from being overlapped or cracked

through the gradual forging forming process and can increase the productivity and at he same time, gain in price competitiveness.

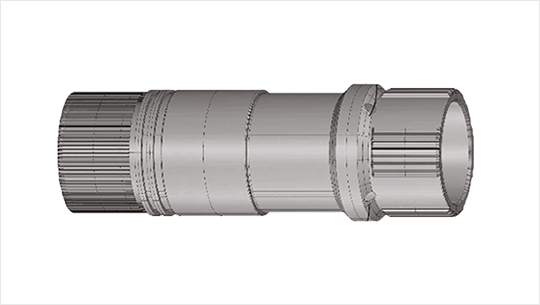

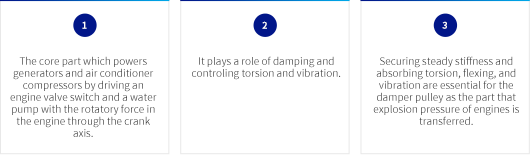

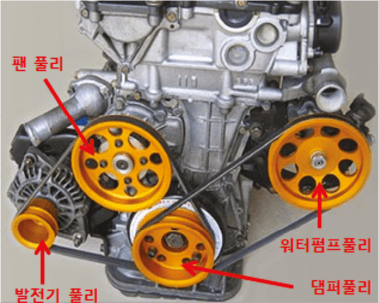

The core part which powers gener-

ators and air conditioner compres-

sors by driving an engine valve

switch and a water pump with the

rotatory force in the engine

through the crank axis.

It plays a role of damping and con-

troling torsion and vibration.

Securing steady stiffness and ab-

sorbing torsion, flexing, and vibra-

tion are essential for the damper

pulley as the part that explosion

pressure of engines is transferred.

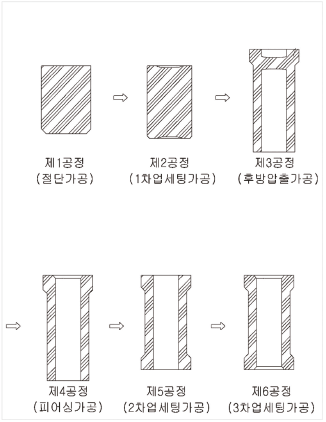

The present invention realizes simplified processes, minimizes the mount of materials used, and provides the effect to achieve economy by reducing defective

products.

The present invention provides promotes improvement of the productivity by reducing production time, achieve economy by reducing the cost of production,

improve formability of strike-bars, and at the same time provides the effect to make a contribution to quality improvement of products by improving durability.

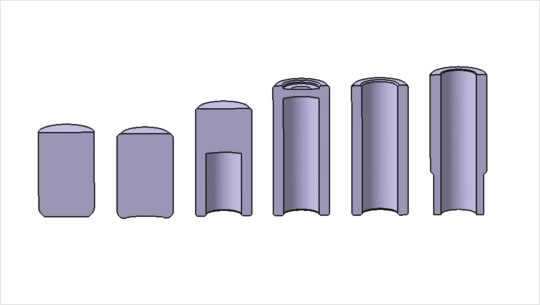

The present invention is the method for forming mounting pipes. This minimizes the amount of mounting pipe materials used and provides the effect to achieve

economy by reducing defective products.

The present invention improved processes to enable simpler, more solid, and more effective manufacture than the past products.

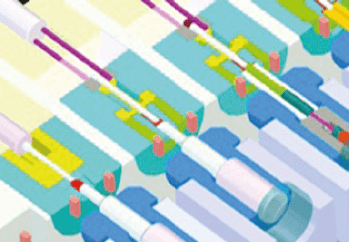

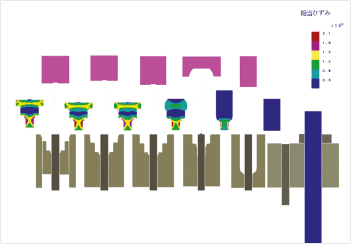

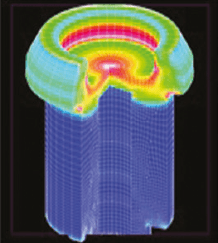

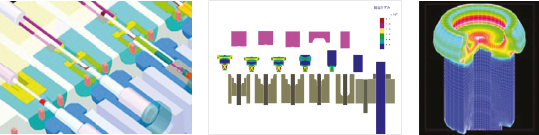

| Volume metal form- ing process struc- tural analysis of 3D simulation mold |

Constant research and development |

Technological information |

Maximization of competitiveness | Technological standardization |

| - Development of new products and technologies - Analyses of the mold structure and improvement of processes |

- Patent administration - Authentication information management |

- Customer satisfaction quality control - Cost reduction by analyzing the structures of parts (msc analysis) |

- Standardization of part and mold drawings - Standardization of technical data |

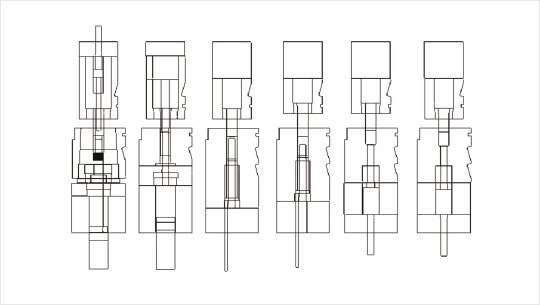

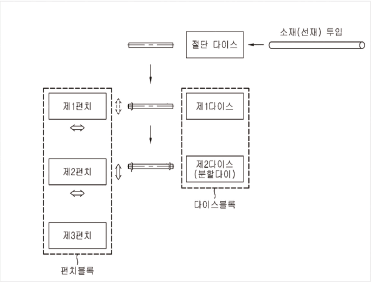

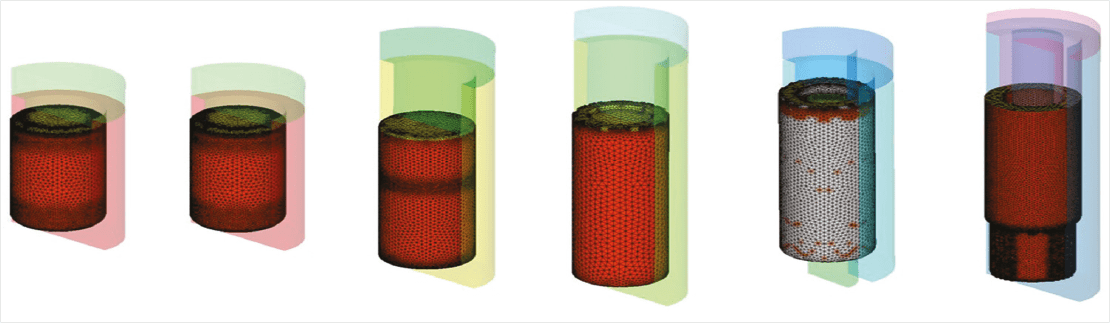

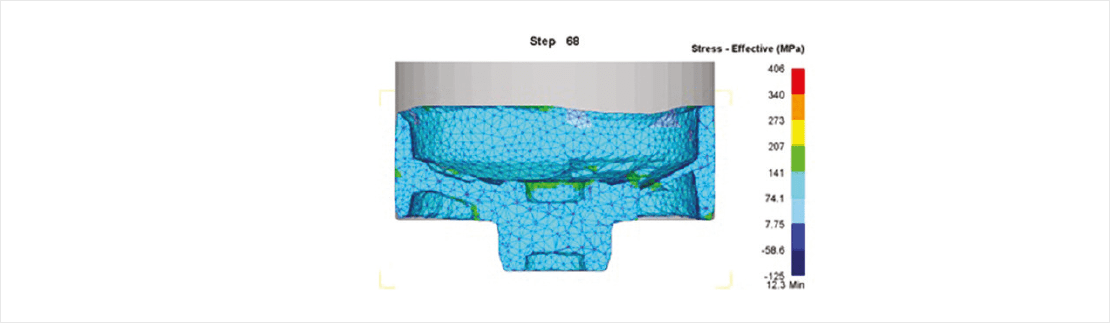

Reaction Shaft Forming analyses by process

Effective deformation rate by process, effective stress by process

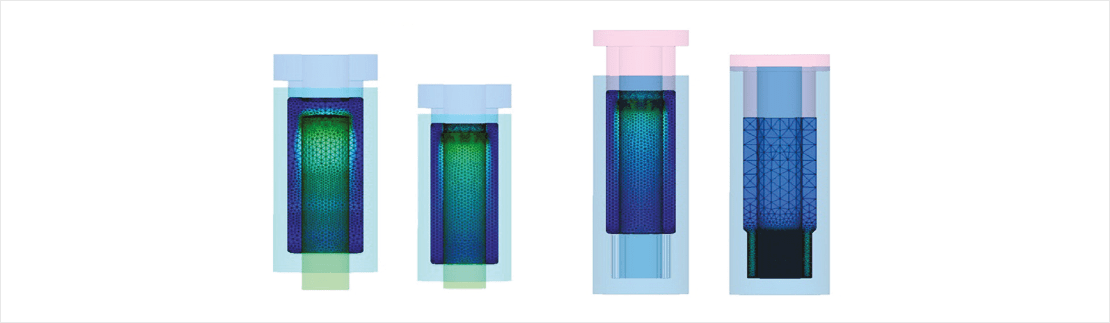

Forming analysis process of damper pulley

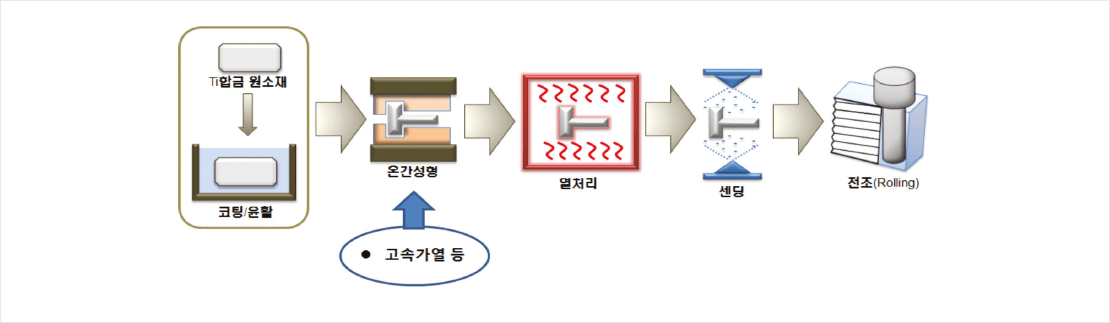

Development of high speed heating technology and automated supply equipment optimized for warm forming of high

strength weight lightening metal, organizational control and preprocessing technology, technological development of

manufacturing process of high strength weight lightening metal parts which utilizes key element technologies including

mold design

Mimetic diagram of developing weight lightening forming parts by the warm forming method

Mimetic diagram of developing weight lightening forming parts by the warm forming method